Our team of specialists is dedicated to developing and refining technologies that meet the highest standards of performance.

Enviromental Protection, Explosion Prevention

Health And Safety Systems

At mist-air, our dust and odour suppression systems are designed with your well-being in mind. By significantly reducing airborne particles and unpleasant odours, our solutions help create safer, healthier environments for workers and surrounding communities. This not only minimises respiratory risks and allergic reactions but also enhances overall air quality, contributing to a more compliant and comfortable workspace. Prioritizing health and safety is at the core of what we do, ensuring that your operations are not just efficient, but also secure and sustainable.

Dust and Odour Suppression Systems Applications

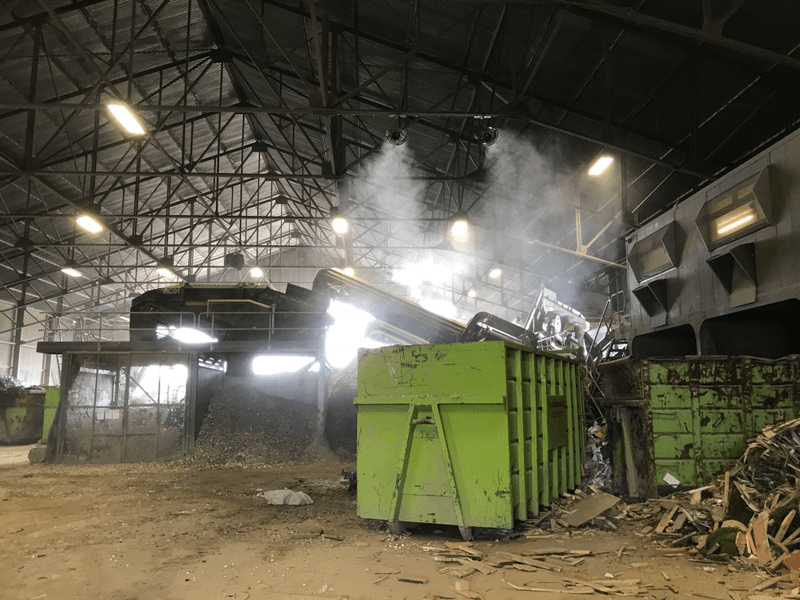

mist-air dust suppression systems can provide significant benefits for industries specialising in wood, timber, and related materials by effectively controlling airborne dust. In woodworking environments, sawdust and wood particles can pose serious health risks to workers, such as respiratory issues, skin irritation, and eye discomfort. Additionally, excessive dust can create a fire hazard and damage machinery. Mist-air systems work by emitting a fine mist of water that binds to dust particles, causing them to settle quickly. This reduces the spread of dust, improves air quality, enhances worker safety, and helps maintain cleaner workspace and equipment, increasing operational efficiency.

Dust suppression systems offer valuable benefits for industries specialising in metalworking, where dust and fine particles from processes like cutting, grinding, and polishing can pose serious health and safety risks. Metal dust can lead to respiratory problems, skin irritation, and eye damage for workers, and can also create explosion hazards, particularly with fine metal powders. Mist-air systems work by releasing a fine mist of water that captures airborne metal dust and causes it to settle, improving air quality. This helps protect workers, reduces fire risks, and keeps machinery and workspaces cleaner, leading to safer and more efficient operations.

Dust suppression systems can significantly benefit industries specialising in glass manufacturing and processing, where dust and fine particles from cutting, grinding, and shaping glass can pose health and safety risks. Glass dust can irritate the respiratory system, skin, and eyes, and can accumulate on machinery, reducing efficiency. Mist-air systems release a fine mist of water that binds to the dust particles, causing them to settle. This reduces the spread of airborne dust, improves air quality, and helps maintain a safer, cleaner work environment. It also enhances equipment longevity by preventing dust build-up, improving overall operational efficiency.

Dust suppression systems provide essential benefits for industries dealing with gypsum and plasterboard production, where dust from cutting, sanding, and handling can be a major issue. Gypsum dust is fine and can easily become airborne, leading to respiratory problems, skin irritation, and eye discomfort for workers. Additionally, the dust can accumulate on machinery, reducing operational efficiency. Mist-air systems release a fine mist of water that captures the dust particles, causing them to settle out of the air. This improves air quality, enhances worker safety, and keeps machinery cleaner, leading to smoother and more efficient production processes.

Dust suppression systems are highly beneficial for industries specialising in brick manufacturing and silica handling, where dust from cutting, grinding, and shaping materials can pose serious health and safety concerns. Silica dust, in particular, is hazardous and can cause respiratory diseases like silicosis if inhaled over time. Brick dust also contributes to poor air quality and can affect workers’ health and machinery performance. Mist-air systems work by releasing a fine mist of water that captures and settles dust particles, reducing airborne contaminants. This enhances air quality, protects worker health, reduces fire risks, and helps keep machinery and workspaces clean for more efficient operations.

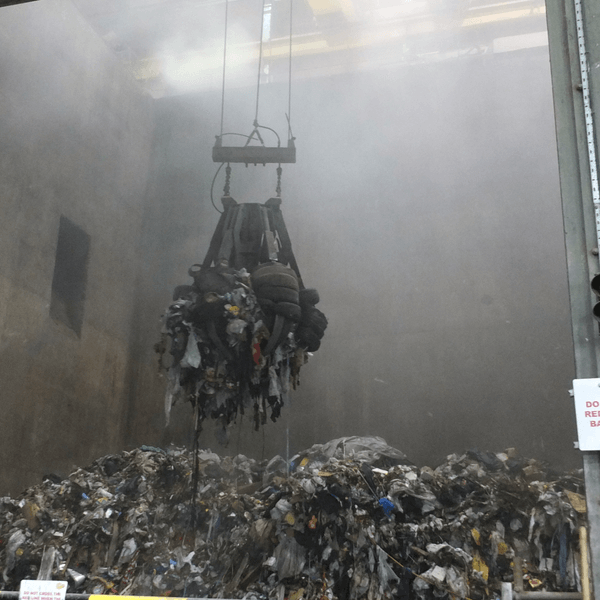

Dust suppression systems are crucial for Material Recovery Facilities (MRFs) and Waste Transfer Stations (WTS), where dust and airborne particulates from waste sorting, processing, and transport can create significant health and environmental issues. Dust generated from mixed waste, construction debris, and recyclables can lead to respiratory problems, reduced air quality, and create an unpleasant working environment. Mist-air systems release a fine mist of water that binds with dust particles, causing them to settle. This minimises airborne dust, enhances worker safety, improves site cleanliness, and helps comply with health and safety regulations, ensuring smoother and safer operations.

Dust suppression systems are highly beneficial for foundries, where processes like casting, grinding, and material handling generate large amounts of dust and fine particulate matter. Foundry dust, often containing hazardous substances like silica and metal particles, can pose serious health risks such as respiratory issues and long-term diseases. Additionally, airborne dust can accumulate on equipment, reducing operational efficiency and increasing maintenance costs. Mist-air systems emit a fine mist of water that binds to dust particles, causing them to settle quickly. This improves air quality, protects workers’ health, reduces fire hazards, and keeps the workspace cleaner, enhancing overall efficiency and safety in foundry operations.

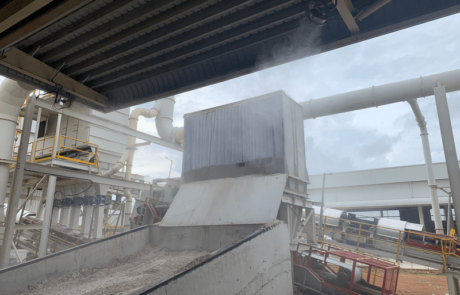

Dust suppression systems provide crucial benefits for quarries and stone processing facilities, where activities such as drilling, crushing, and cutting generate large amounts of dust. Dust from stone, gravel, and other aggregates can be hazardous, causing respiratory issues for workers and creating visibility problems that increase accident risks. Additionally, fine particles, especially silica dust, can pose long-term health risks. Mist-air systems release a fine mist of water that binds to dust particles, causing them to settle, reducing airborne dust. This improves air quality, enhances worker safety, and ensures a cleaner working environment, helping facilities comply with safety regulations and improve operational efficiency.

Dust suppression systems offer significant advantages for the paper industry, where dust from paper production, cutting, and recycling can accumulate in the air. Paper dust can pose health risks to workers, leading to respiratory issues, eye irritation, and skin problems. Additionally, excessive dust can create fire hazards, particularly in environments where fine paper particles are present. Mist-air systems work by releasing a fine mist of water that binds to dust particles, causing them to settle. This improves air quality, reduces fire risks, and keeps machinery cleaner, leading to safer working conditions and more efficient production in paper mills and recycling facilities.

Odour suppression systems can significantly benefit equine environments by reducing airborne dust and particulates that may negatively affect horse health. In stables, arenas, and other equine facilities, dust from bedding, feed, and the ground can cause respiratory issues, irritate the eyes and skin, and contribute to poor air quality. Mist-air systems work by releasing a fine mist of water, which binds to dust particles and causes them to settle, minimising inhalation risks. This creates a cleaner, healthier atmosphere for both horses and handlers, enhancing comfort, respiratory health, and overall performance.

Odour suppression systems can provide significant benefits for food waste processing facilities, where dust, odours, and airborne particles from organic materials can create serious health and hygiene concerns. In facilities where food waste is sorted, shredded, or composted, dust from dry materials and organic particles can become airborne, leading to respiratory issues, odour problems, and contamination risks. Mist-air systems release a fine mist of water that traps dust particles and odours, causing them to settle. This improves air quality, reduces unpleasant odours, enhances worker safety, and ensures compliance with hygiene standards, creating a cleaner and more efficient work environment.

Odour suppresion systems that combine odour neutralisation and dust absorption are highly effective in industries where air quality is a major concern. These systems release a fine mist of water infused with specialised neutralisers that not only bind to dust particles, causing them to settle, but also eliminate unpleasant odours at the source. This dual function is particularly beneficial in waste management, food processing, recycling, and other industries where dust and strong odours can impact the work environment. By reducing airborne particulates and neutralising odours, these systems improve air quality, enhance worker comfort, ensure compliance with health and safety regulations, and create cleaner, more efficient operations.

Case Studies

Mist-Air

Leaders in dust suppression & odour absorption technology

With over 200 happy customers, mist-air is a trusted leader in dust and odour suppression, providing effective solutions that enhance safety and cleanliness across various industries.

Supporting over 50 industries, mist-air provides essential dust and odour suppression solutions, ensuring cleaner, safer environments across diverse sectors.

Your Trusted Partner

Specialist in Dust and Odour Suppression Systems

50 years of British engineering excellence