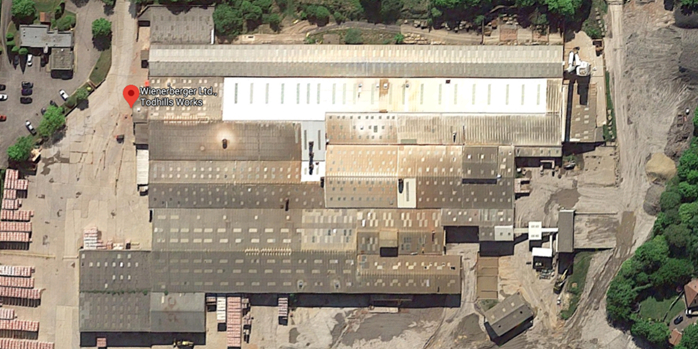

Todhills Works, Bishop Auckland Case Study

A Case Study In Brick Dust Suppression

Challenge:

Founded in 1819 Wienerberger AG is an Austrian brick maker which is the world’s largest producer of bricks, and the number one manufacture of clay roof tiles, ceramic pipes and as concrete pavers in Europe

With more than 200 production sites globally, mist-air has successfully provided dust suppression systems at many of their UK factories. Controlling dust from clay infeed box feeder, clay prep, conveyer transfer points, extruders, sanding areas, setters, de hackers and kiln car repair areas.

| Location | Todhills Works |

|---|---|

| Customer | Wienerberger |

| Sector | Brick |

The Mist-air Solution:

mist-air is able to produce a micro fine fog that creates no wetting in this moisture sensitive environment. High level mist-air fan assisted manifolds are located to suppress airborne dust and silica as they are created and also to remove this background build-up of dust from various processes on site this can be from ill-fitting guards, air movement or vehicle movement. mist-air also treat localised areas such as waste belts and waste skips.

The mist-air system at Todhills Works was installed in 2015 to control airborne respirable silica created in the clay prep, transfer cars and setter area .

Get In Touch